About LINEGEAR Lenses

LINEGEAR make custom replacement lens, rubber parts and other parts for Oakley X-Metal series.

We use the lenses which meet the standards of the Household Goods Quality Labeling Act by the Ministry of Economy, Trade and Industry. With the cooperation of Lens-Ya Jinbocho Shop, which is the only lens specialty shop in Japan.

Almost fof all our lenses have ANSI(United States), EN ISO 12312-1(European Union) and AS/nZS 1067(Australia and New Zealand) .

All products are used the high function, high grade lenses.

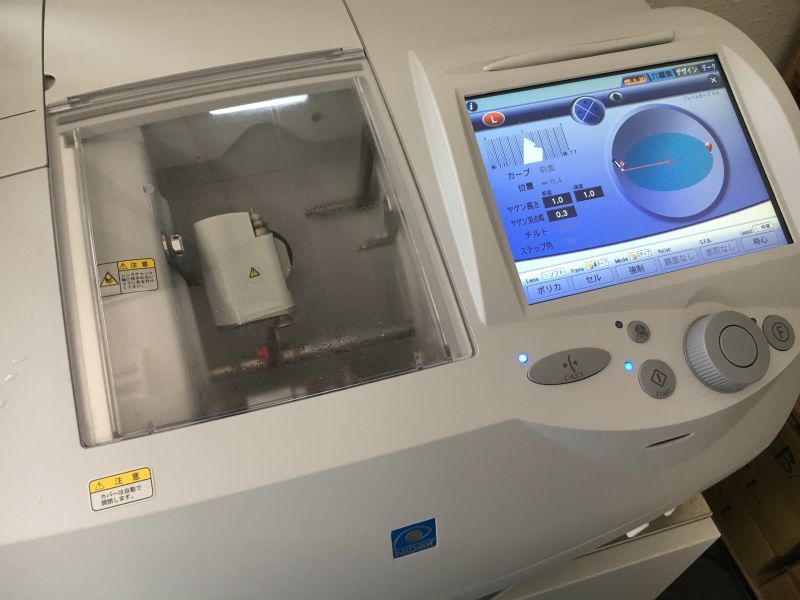

We are cutting lenses in our factory in Japan by using the edging machine NIDEK ME-1200 one by one for you.

NIDEK ME-1200

The products which we sell, had been developed by LINEGEAR originally and is not part of Oakley company.

::::::::::Function:::::::::::

Polycarbonate non-polarized Lenses

Lens curve: 8, Thickness:1.7mm - 1.5mm, Raw lens is round & curve lens, Blocking 100% of UVA & UVB, Prism correct function.

Click on a picture to enlarge ↑

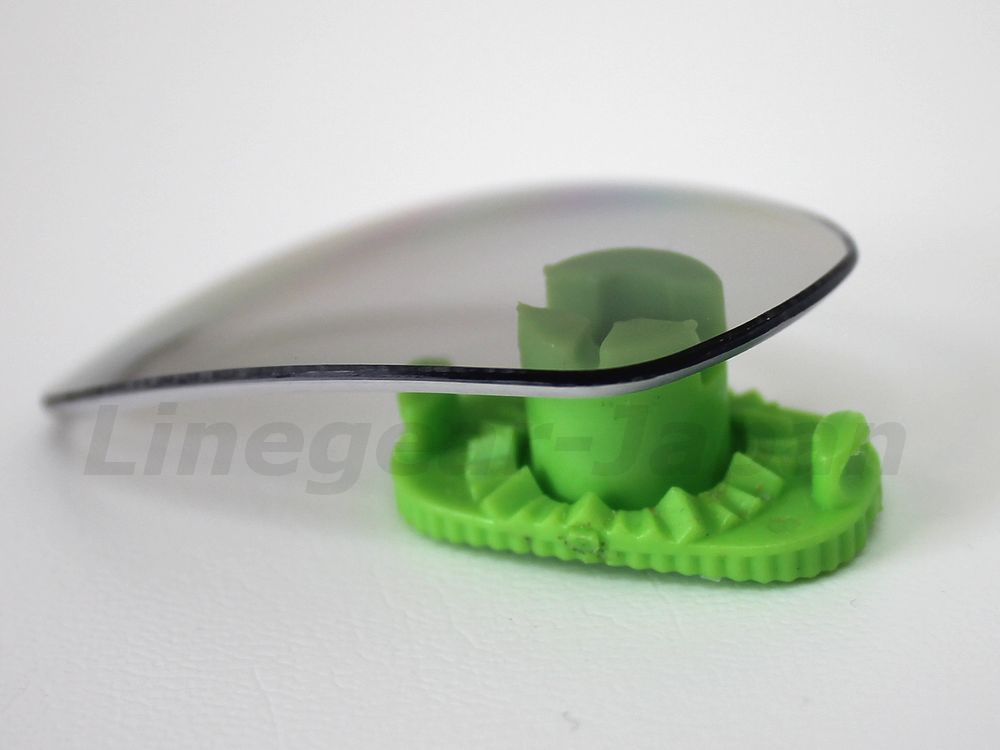

Polycarbonate Polarized Lenses

Lens curve: 8, Thickness : 1.6mm - 2.0mm, Raw lens is rectangle & curve, Blocking 100% of UVA & UVB, Prism correct function. (A small number of lenses doesn't have this function, it is stated in each item description).

Click on a picture to enlarge↓

NXT Lenses

Lens curve: 8, Thickness : 2mm to 1.8mm, Raw lens is round & curve lens, Blocking 100% of UVA & UVB, Prism correct function.

We are Authorized distributor of NXT lens. We have a business partnership with I.C.Japan.

I.C.Japan is only the distributor company which can produce NXT lenses in Japan market.

It means, all of our lenses are coming from ESSILOR SUN SOLUTION.

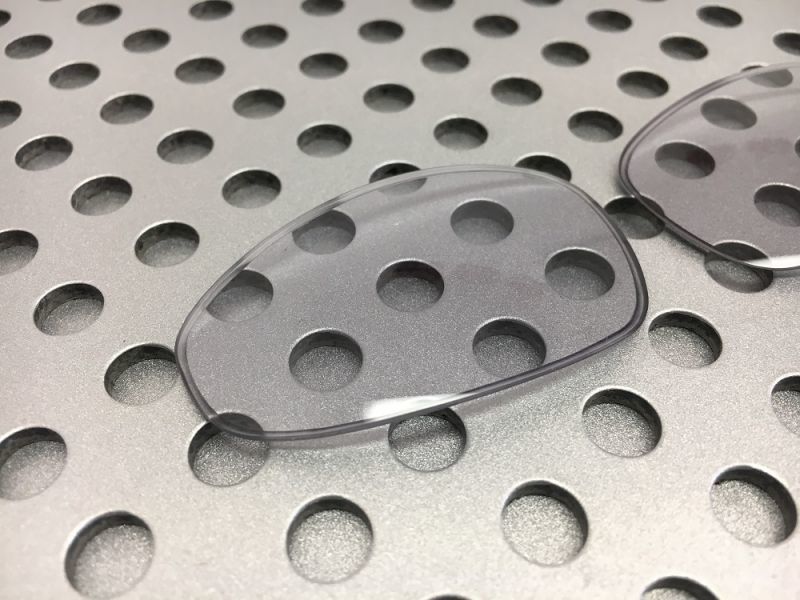

Lenses Edgeing

Each pair of lenses are hand finished after cutting with a precision edgeing machine. Before we ship lenses to our customer, we check the fitting status by installing the lenses to our sample frames.

--Detail process to finish the lenses and check fitting one by one--

We made final adjustment, one by one by hand, to make sure all our lenses are perfectly fit to your frame and to check the distortion no exist and scratch free before shipping out to the customer.

In our almost 10 years experience, we came to understand and master the skills to cut lenses which will fit perfetly in your X-Metal. The X-Metal were originally hand finished and each frame tend to have a small individual difference, although at a very small percentage.

--Delicate work--

We handle lenses carefully, and we adjust the edge parts of the lenses very attentively.

Policarbonate lenses get distorted easily if using a strong pressed screws.

If you feel dizzy and you may avoid pressing the orbital screw too much.

We do our best to measure each lens with the original sample and they will be perfectly fit into your frames.

Lenses Distortion

Linegear's lenses which we produce are all 8 base curve lens. Due to high curve lenses, it is easy to have distortion on the edge of the frame. We make effort to avoid such distortion, so it means our lenses are little bit smaller than OEM lenses.

Some user feel very sensitive to lenses distortion. If you feel an uncomfortable from our lenses after you install our lens to your frame, kindly contact us for consultation.

Light transmission through the lens (Transmissivity)

We describe about it on Item description for each lens.

How to handle the lenses

Please handle your mirrored lenses carefully, because they scratch easily.

Please remove dirt by washing with water, and wipe it off with a clean cloth or a lens cleaning cloth, when wiping them clean of dirt.

Do not leave mirrored lenses wet. It could cause discoloration of the lenses.

Do not soak polarized lenses in water for a long time. It could cause damage to their function.

Although the lenses will not be affected when they get slightly wet, please be aware that the lenses are sensitive to water when you use them.